4-point System Fabric Inspection Pdf

Visual Inspection and Grading of. The inspection area at a visual inspection speed. Fabric may be. 100 yards each is inspected using a 4-point system. 4 Points system for fabric inspection and question related to 4 point system. The four-point system derives its name from the basic grading rule. He or she must be well versed with the 4-point fabric inspection system. Jun 11, 2014 Suntech brand Fabric Inspection Machine for all kinds of fabrics. Automatic; Perfect edge alignment and tension controlling. Many options could be built-in.

Fabric Quality Inspection: The quality of a final garment depends on the quality of a fabric when it is received as a roll. Even the most outstanding manufacturing methods cannot compensate for defective materials. Normally, 10% of the rolls that are received are evaluated based on a four-point system. This way, fabric related quality problems can be avoided before it is put into production' Four- Point System: Amount to select: Inspect at least 10% of the total rolls of the shipment. Selection of rolls: Select at least one roll of each color. If more than one role must be selected, then choose the additional roles in proportion to the total number of roles per color received.

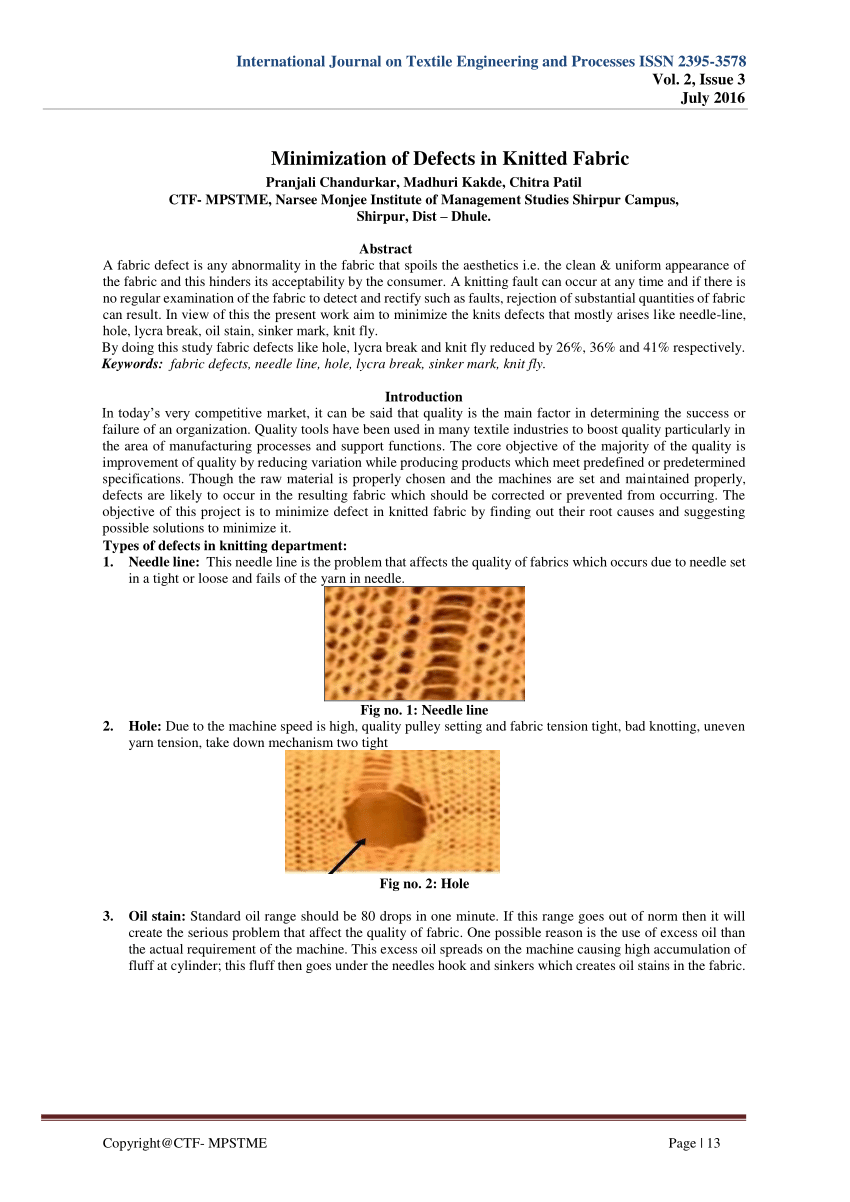

Defect Classification (Four- Point System): Size Defect Penalty. -3 inches or less: 1 Point -Over 3 inches, but less than 6: 2 Points -Over 6 inches, but less than 9: 3 Points -Over 9 inches: 4 Points The length of the defect is used to determine the penalty point. Only major defects are considered. No penalty points are assigned to minor defects. (A major defect is any defect that would cause a final garment to be considered a second.) Major Defects: Major woven fabric defects include but are not limited to slubs, holes, missing yarns, yarn variation, end out, soiled yarns, and wrong yarn. Major dye or printing defects are out of register, dye spots, machine stop, color out, color smear, or shading. Ipadian For Windows 7. Acceptance Criteria and Calculation: 40 points per 100 yards is the acceptable defect rate # of Points per 100 yds = # of penalty points x 100 Yds inspected.width tolerance +/-1' acceptable Inspection Procedure: Determine the amount to inspect 10%).

Select the rolls to inspect. Put the rolls on the inspection machine or other viewing device. Cut off a 6 inch piece across the width off the end of the roll. Mark the right and left side of the strip. Stop the inspection process every 50 yards and use the strip to check for any shading problems.

Also make sure to check the end of the role. Inspect for visual defects with the light on at a speed slow enough to find the defects.

(The fabric must be checked at a slow rate in order to effectively find flaws). Sometimes you may have to turn the light off to see how a flaw will affect the appearance of a garment. Check that the roll contains the correct yardage as stated by the piece goods source. Check for skewed, biased, and bowed fabric. Game Mar Heaven Ps2 here. Mark any defects to the side with colored tape so that they can be easily found and noted. Record any defects. Fabric Quality Inspection: The quality of a final garment depends on the quality of a fabric when it is received as a roll.